Many users often ask the price of the steel pipe shot blasting machine, in fact, the price has no absolute number, and the equipment is very much related, a steel pipe shot blasting machine market guidance price is in the range of 10-1 million yuan, the factors affecting the price of a steel pipe shot blasting machine are the following:

1, according to the customer's production power and requirements

For example, the diameter of a single steel pipe is 1000mm, the length is 12000mm, and the shot blasting quality reaches Sa2.5 or above. The cleaning speed reaches more than 6 meters per minute. It is required to equip four shot blasting machines with a power of 15KW to meet the requirements, on the contrary, the diameter of the steel pipe is less than 1000mm while ensuring the quality of the shot blasting, the speed can reach more than 6 meters per minute. If the diameter of the steel pipe is greater than 1000mm, the speed will be less than 6 meters per minute under the premise of ensuring the quality of the shot blasting.

2, electrical equipment

Whether to choose high quality electrical parts, such as Siemens Schneider ABB, etc. Can also choose Zhengtai Delixi and so on

3. Purchased standard parts and bearings

Bolts are divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 8.8, 9.8, 10.9, 12.9, among which the raw material above 8.8 grade is alloy steel quenching treatment, and its strength reaches 39-44HRC. Bearings are divided into imported NSK domestic Harbin shaft

4, traditional equipment and automation

Traditional shot blasting equipment is low and useful, requiring manpower to cooperate with equipment operation and loading and unloading. Automatic equipment refers to the equipment and equipment to achieve fully automatic control (fully automatic is not necessarily not the choice of high-end accessories, mid-end accessories can also be achieved, depending on requirements) from the feeding, unloading, unloading PLC control, electrical aspects to add photoelectric detection and sound and light alarm functions (such as bearing 150 RPM, bearing speed will decrease before damage, This is the sound and light alarm will start, easy to repair several maintenance, on the contrary, traditional equipment does not have this function, to bring inconvenience to maintenance).

5, the weight of the steel pipe

The component of the steel pipe determines the thickness of the plate of the equipment and the bearing force and driving power of the conveying system.

6. Other details

The environmental protection pulse dust removal system is selected to add 2 layers of seals to bearings that reach the emission standard ≤100mg/m3 to prevent the bearing from sand dust damage and extend the service life. The lifting machine is selected with anti-reverse gear to prevent the lifting machine from reversing due to component after shutdown.

Qingdao Reikinggroup Environmental Protection Technology Co.,Ltd.

Qingdao Reikinggroup Environmental Protection Technology Co.,Ltd. 中文版

中文版 English

English

Product Center

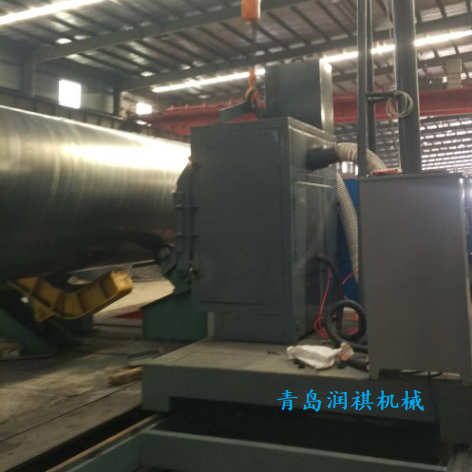

Product Center Steel pipe shot blasting machine

Steel pipe shot blasting machine

*86 15376423339

*86 15376423339