Working principle

The large wind power tower barrel with a diameter of more than 2000mm is placed on the fixed wheel bracket for 360 degree rotation. The special shot blasting machine for the inner and outer walls of the mobile tower barrel starts the dust removal system, the elevator separator, the shot blasting device, etc., and then starts the ground rail drive system again to advance in the longitudinal and horizontal direction and carry out the shot blasting treatment on the inner and outer walls of the tower barrel. In addition, according to the diameter specifications of different tower tubes, the Siemens photoelectric detection system can realize hydraulic automatic height measurement, and the shot blasting device automatically adjusts the best shot blasting distance along with the detection, which provides help for high-quality shot blasting strengthening and operation safety. The inner and outer walls can pass the shot blasting at one time, and the cleanliness of the surface can reach Sa2.5 or above. The strengthening effect of shot blasting is highlighted and the adhesion for anti-corrosion is improved.

Qingdao Reikinggroup Environmental Protection Technology Co.,Ltd.

Qingdao Reikinggroup Environmental Protection Technology Co.,Ltd. 中文版

中文版 English

English

Product Center

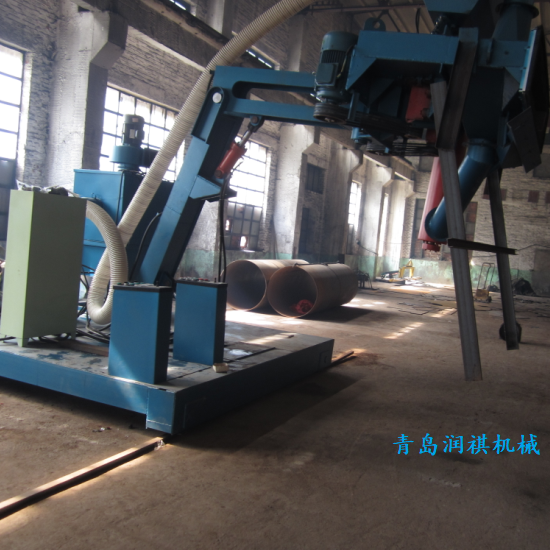

Product Center Wind power tower shot blasting machine

Wind power tower shot blasting machine

*86 15376423339

*86 15376423339